Making Sure Toughness with Thorough Pipeline Welding Inspection

Making Sure Toughness with Thorough Pipeline Welding Inspection

Blog Article

Comprehensive Guide to Pipe Welding Examination: Making Sure Integrity and Safety And Security in Pipeline Construction and Upkeep

The stability and security of pipes are extremely important in today's facilities landscape, underscoring the critical duty of welding assessment in pipeline building and construction and maintenance. An extensive guide on this subject not just highlights the requirement of evaluating weld high quality but likewise addresses the various inspection techniques available, such as radiographic and ultrasonic screening. By recognizing typical issues and their ramifications, stakeholders can execute finest techniques that guarantee conformity and longevity. Nevertheless, the intricacies involved in welding examination raise important inquiries about market standards and the progressing modern technologies that may redefine these methods.

Relevance of Welding Inspection

Welding evaluation plays a vital function in making sure the honesty and safety of pipeline systems. It functions as a basic procedure that validates the top quality and dependability of welded joints, which are typically the most susceptible points in pipe building and construction. Via methodical assessment, inspectors can identify potential issues such as cracks, porosity, and incomplete combination, which may endanger the structural integrity of the pipe.

The relevance of welding assessment extends past plain conformity with industry criteria; it likewise safeguards public health and wellness and the environment. If failures happen, pipelines lugging hazardous products posture substantial risks. Reliable assessment protocols aid protect against leaks and ruptures, minimizing environmental damages and safeguarding areas. Moreover, extensive inspections can boost the durability of pipe systems, decreasing the demand for costly repair services and downtime.

Along with making sure safety and conformity, welding assessment fosters a society of quality control within organizations. By prioritizing evaluation throughout the welding process, firms can construct a track record for reliability and excellence, inevitably leading to enhanced client self-confidence and organization possibilities (Pipeline Welding Inspection). Thus, the significance of welding evaluation can not be overemphasized in the context of pipe building and upkeep

Secret Welding Procedures

Different welding procedures are used in pipe construction, each with its own advantages and applications. Amongst one of the most widely used techniques are Protected Steel Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Gas Steel Arc Welding (GMAW) SMAW is preferred for its flexibility and capability to execute well in different ecological problems, making it suitable for field applications.

GTAW, typically referred to as Tungsten Inert Gas (TIG) welding, is recognized for its capacity to generate high-grade welds with outstanding control over warmth input, making it suitable for thin-walled pipelines and stainless-steel materials. GMAW, or Steel Inert Gas (MIG) welding, uses high deposition rates and is efficient for large jobs, commonly employed in the manufacture of pipes in controlled settings.

Furthermore, Immersed Arc Welding (SAW) is used for its deep infiltration and high performance, specifically in the building and construction of large-diameter pipelines. Each of these processes adds to the general honesty and security of pipe buildings, enabling welders to select one of the most suitable approach based on product type, task demands, and ecological conditions. Comprehending these key welding processes is crucial for effective pipeline welding examination.

Typical Issues and Their Effect

Porosity, defined by little gas pockets trapped within the weld, weakens the product and can cause leaks. Cracks, which might happen because of thermal stresses or improper air conditioning, can propagate and result in architectural failure under pressure. Damaging, where the base metal is eroded along the weld grain, decreases the effective cross-section of the pipe, boosting the risk of crack.

Incomplete fusion takes place when the weld steel does not appropriately bond with the base metal, causing weak locations that may fail under stress and anxiety. Slag incorporation, the entrapment of non-metallic material within the weld, can also deteriorate the joint's stability. Identifying and resolving these problems early in the building and construction procedure is essential to ensuring the lasting reliability and safety of pipe systems, thereby protecting both the environment and the framework.

Inspection Strategies and Tools

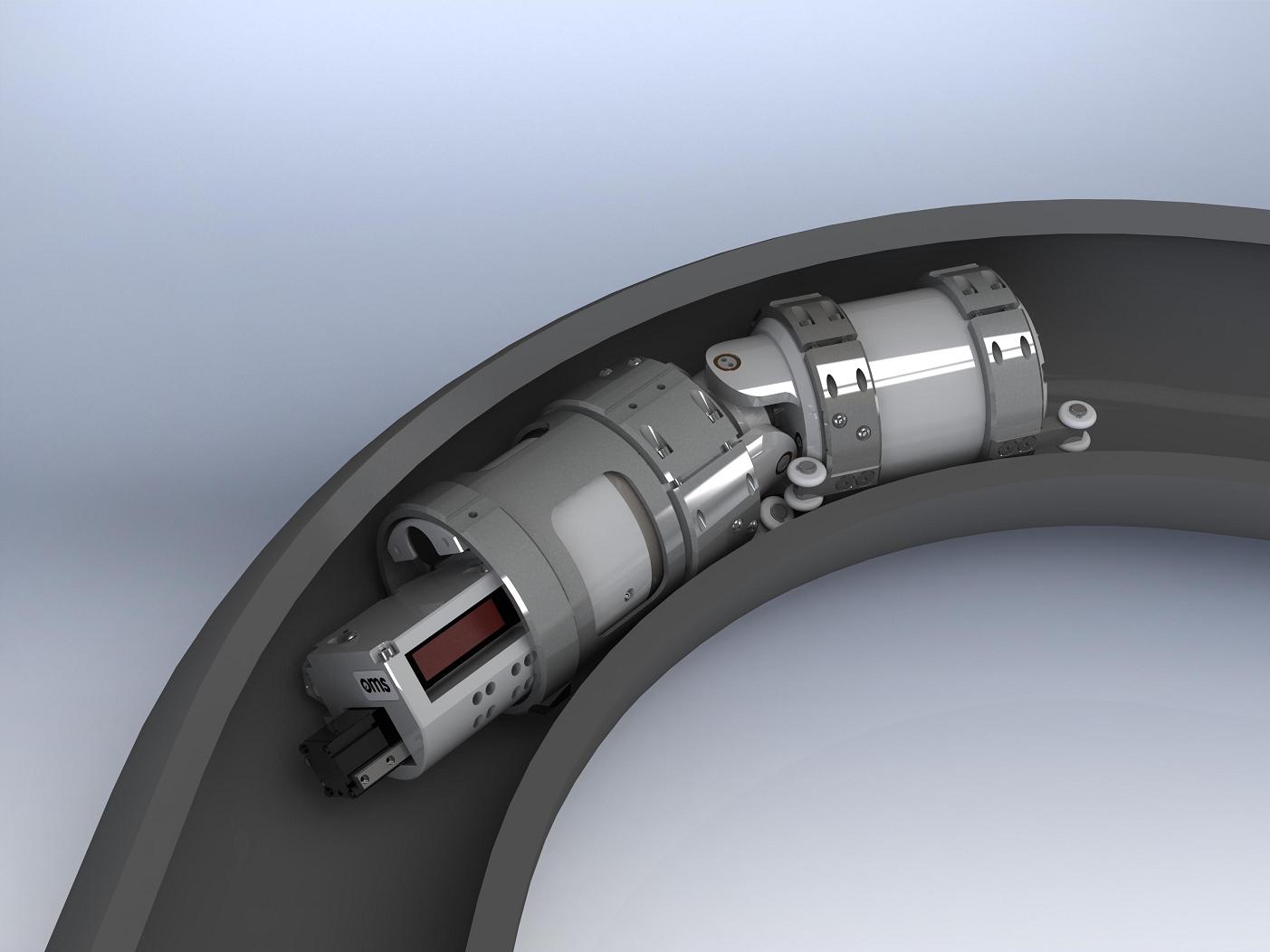

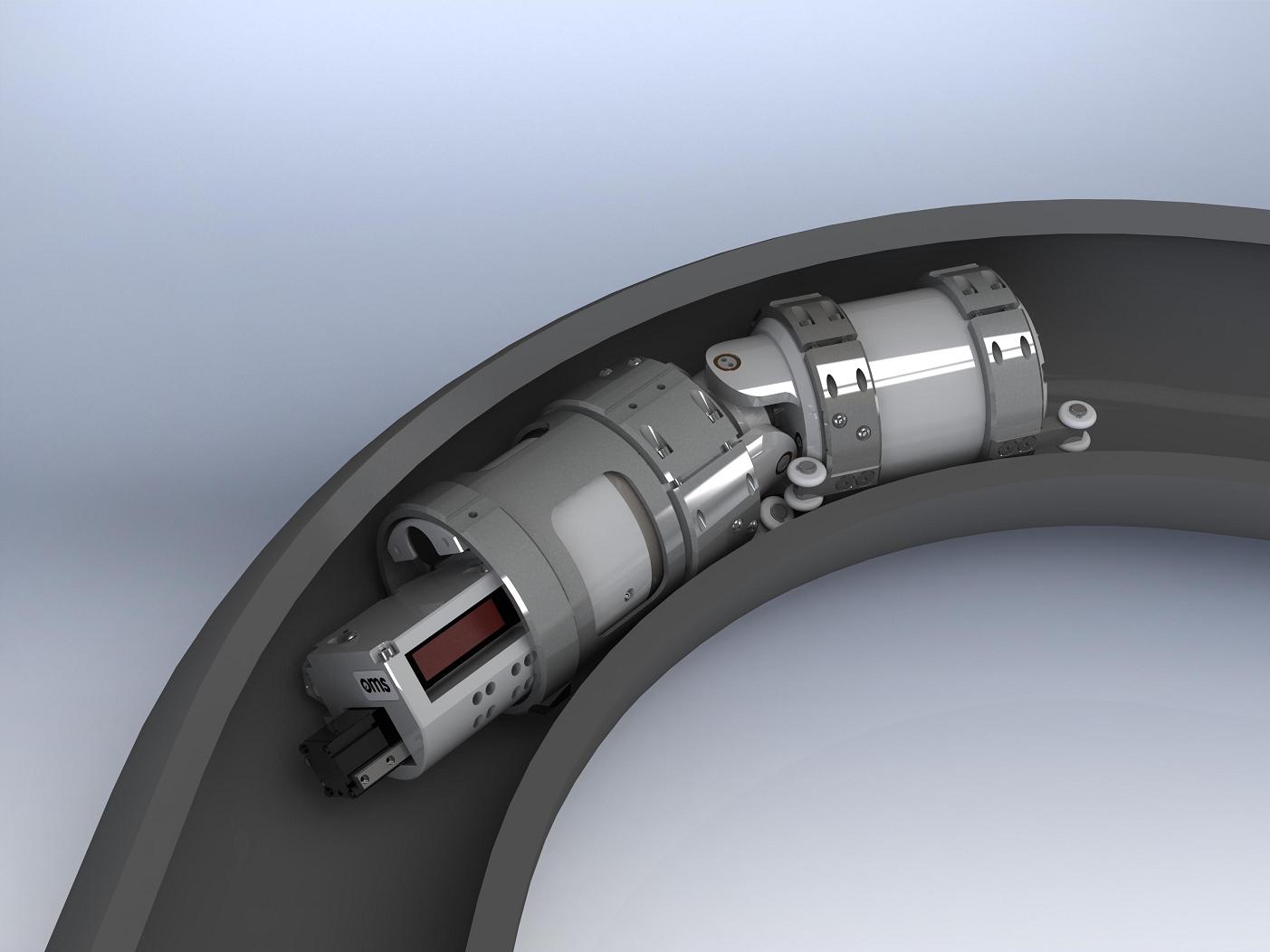

Aesthetic evaluation is the first line of protection, enabling assessors to determine surface irregularities, misalignment, or other noticeable problems. Ultrasonic screening utilizes high-frequency audio waves to find internal problems, providing exact depth measurements and home identifying problems without harming the weld. Radiographic testing uses X-rays or gamma rays to produce photos of the weld, making it possible for the identification of inner voids, fractures, or incorporations.

Magnetic particle screening is specifically efficient for identifying surface and near-surface stoppages in ferromagnetic materials. This method entails applying a magnetic area and fine iron bits to the weld, disclosing defects with the buildup of bits at problem websites.

Along with these strategies, specialized tools such as automated ultrasonic screening devices and electronic radiography systems improve examination precision and efficiency, making sure a comprehensive examination of pipe welds throughout building and construction and maintenance.

Ideal Practices for Conformity

Abiding by best practices for compliance in pipeline welding evaluation is vital for making certain the honesty and safety of the infrastructure. Organizations must establish an extensive high quality administration system that lines up with market requirements such as ASME, API, and AWS. This includes developing comprehensive welding procedures that specify the certifications, materials, and techniques needed for welders.

Routine training and accreditation of assessment workers are vital to preserve high proficiency levels. Assessors need to recognize with different non-destructive testing (NDT) methods, consisting of ultrasonic screening, radiographic screening, and aesthetic assessment, to successfully determine prospective flaws.

Documents plays an essential function in compliance; preserving precise documents my blog of examinations, weld treatments, and workers qualifications aids to make certain traceability and responsibility. Scheduled audits and testimonials of welding practices ought to be performed to recognize locations for enhancement and make sure adherence to established protocols.

Conclusion

In verdict, the implementation of rigorous welding evaluation procedures is vital for making sure the honesty and safety and security of pipe building and upkeep. Constant enhancement in assessment procedures will certainly add to the long life and integrity of pipe systems, emphasizing the critical function of welding assessment in the sector.

The stability and safety and security of pipes are extremely important in today's facilities landscape, emphasizing the crucial role of welding inspection in pipe building and construction and upkeep. Recognizing these essential welding procedures is important for efficient pipeline welding examination.

Sticking to ideal methods for compliance in pipeline welding inspection is critical for guaranteeing the stability and safety and security of the infrastructure.In conclusion, the application of extensive welding inspection methods is paramount for making sure the honesty and safety and security of pipe building and construction and maintenance. Continual renovation in evaluation processes will certainly add to the long life and reliability of pipe systems, underscoring the important role of welding have a peek here examination in the market.

Report this page